Machine fleet

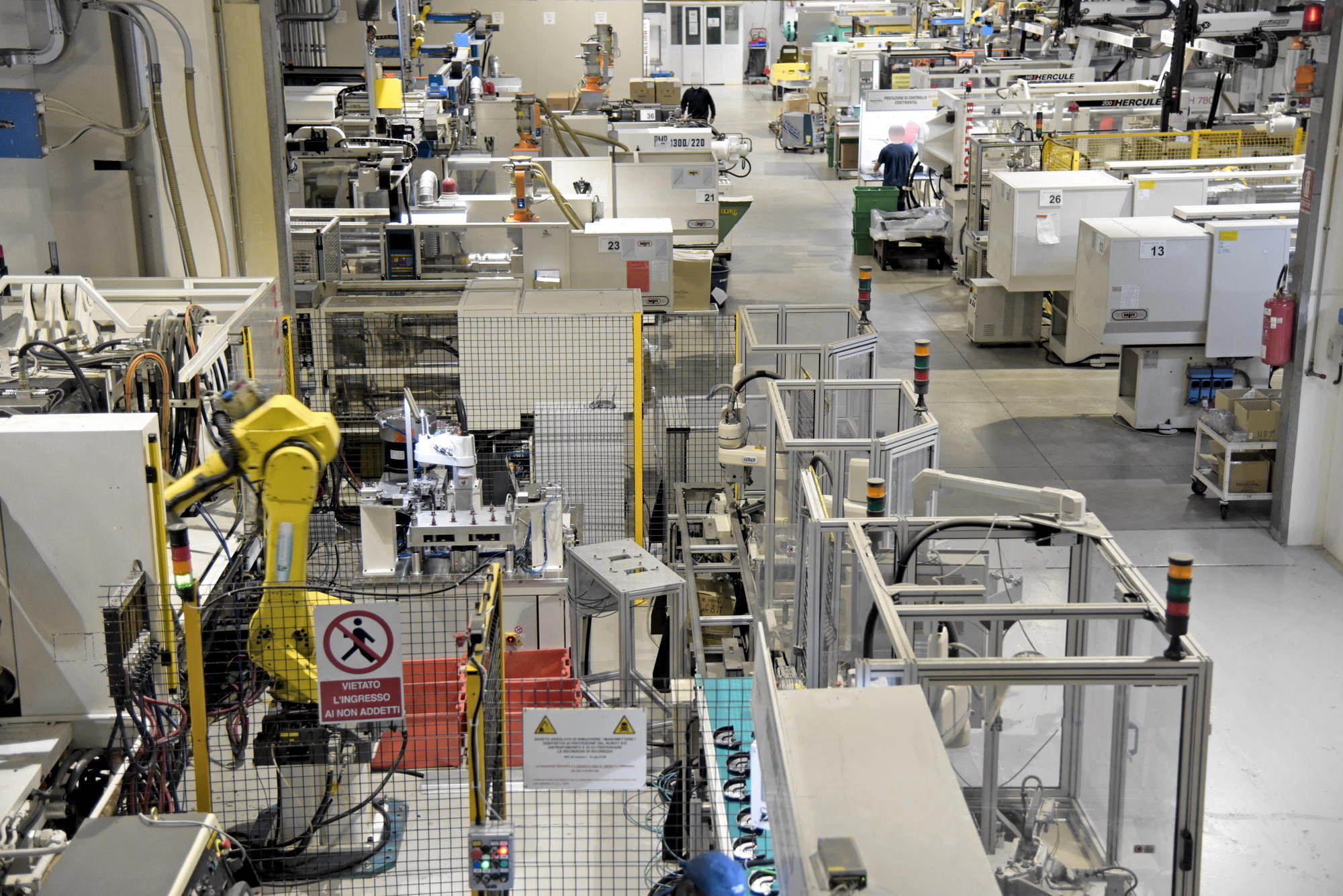

Techpol Srl has three separate production plants covering a total of over 10,000 sq m, allowing it to split the different production areas as well as development and control activities.

An important feature of the Techpol Srl factories is a logistic line that is 250 metres long, connecting the whole production plant to the central quality control area, packaging and storage.

Every day at Techpol Srl, 2,200 shuttles are moving, each of which autonomously covers a distance of around 7 km, between production and packaging, self-regulated by machines.

After unloading the products into the inspection and packing area, each shuttle then moves to the waiting station until it receives a new input to move to the moulding machine to pick up other moulded material.

This is just one of the many solutions put in place by Techpol Srl to cut out activities with no added value, optimising production with a faster means of transport in a cleaner, more efficient working environment.

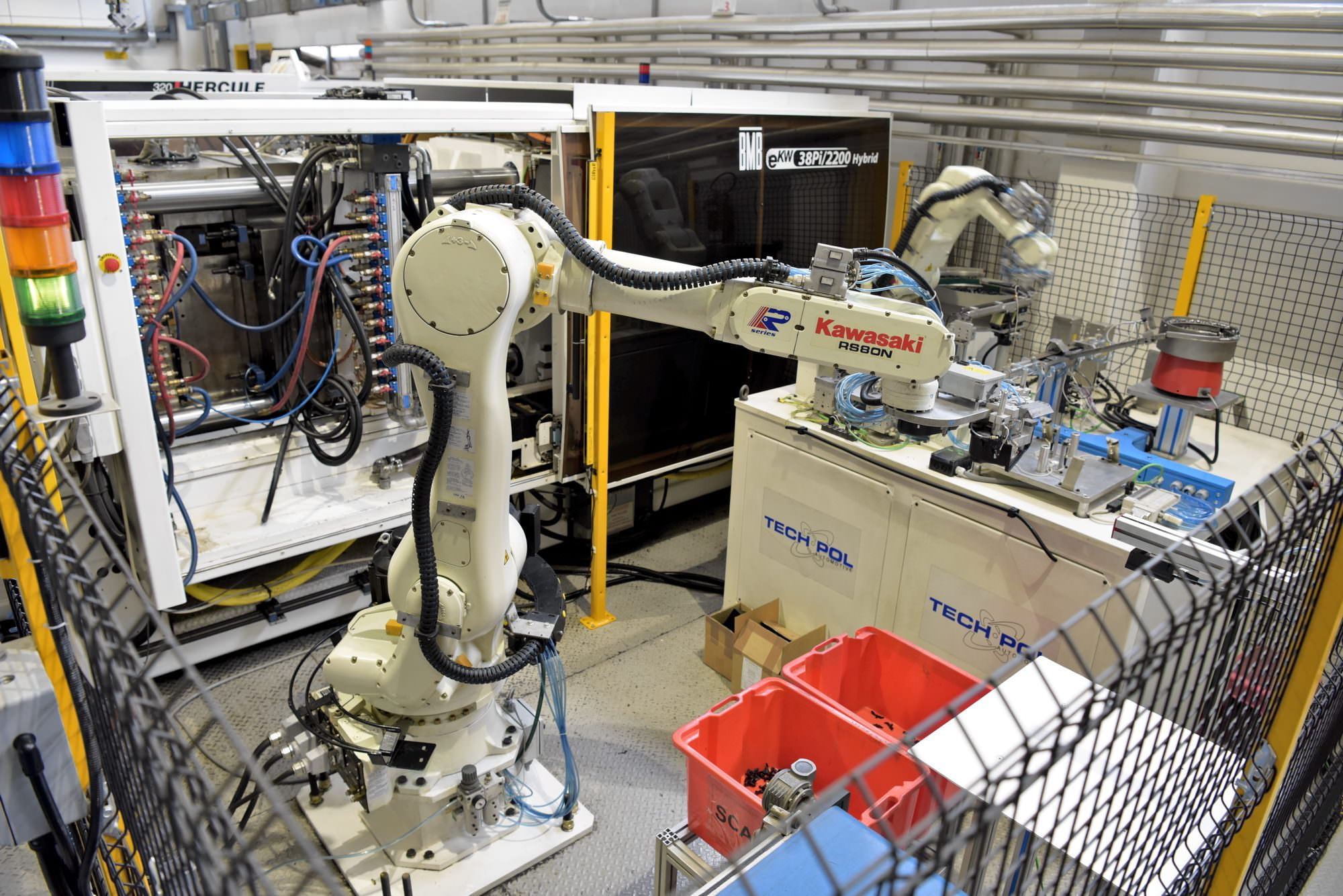

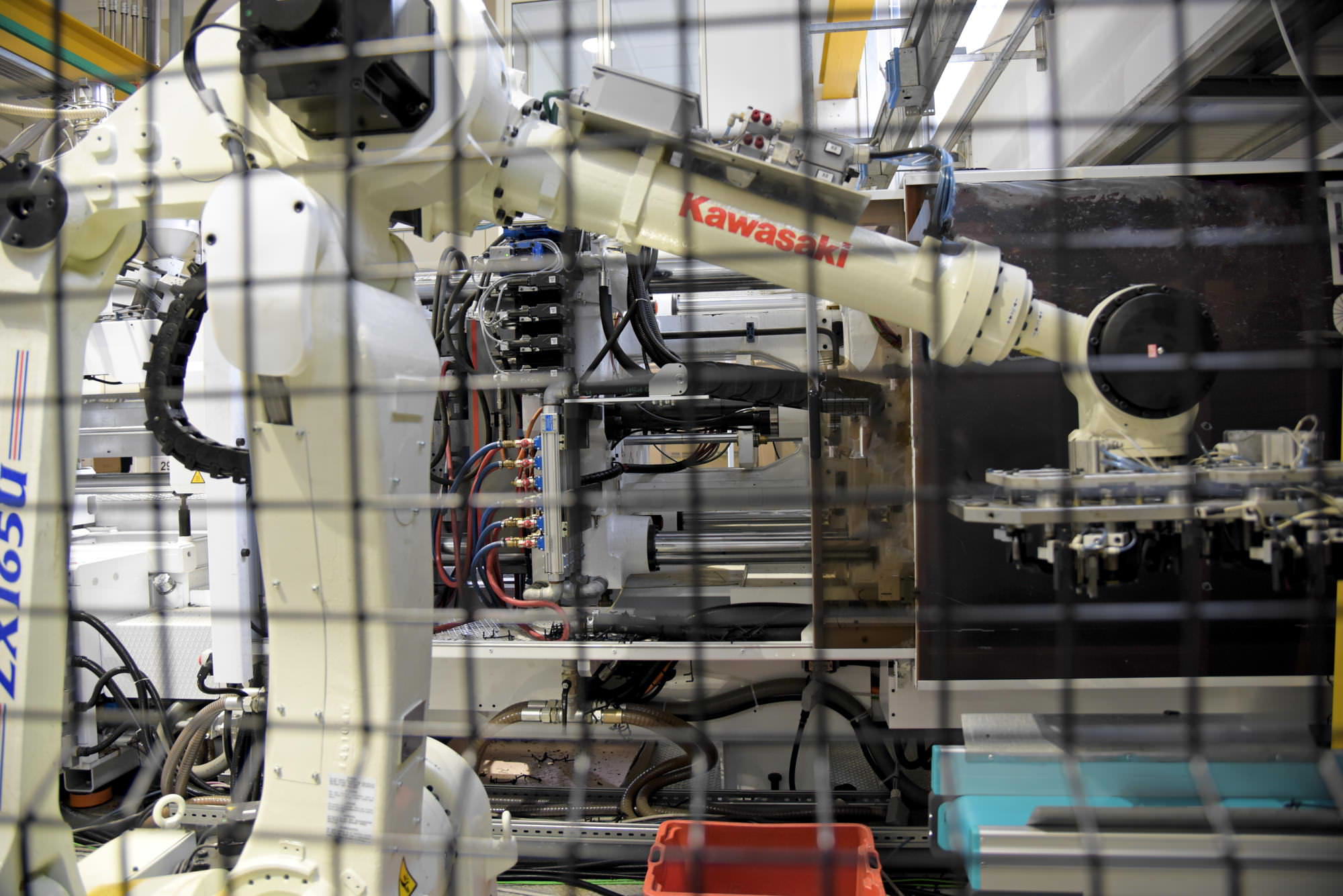

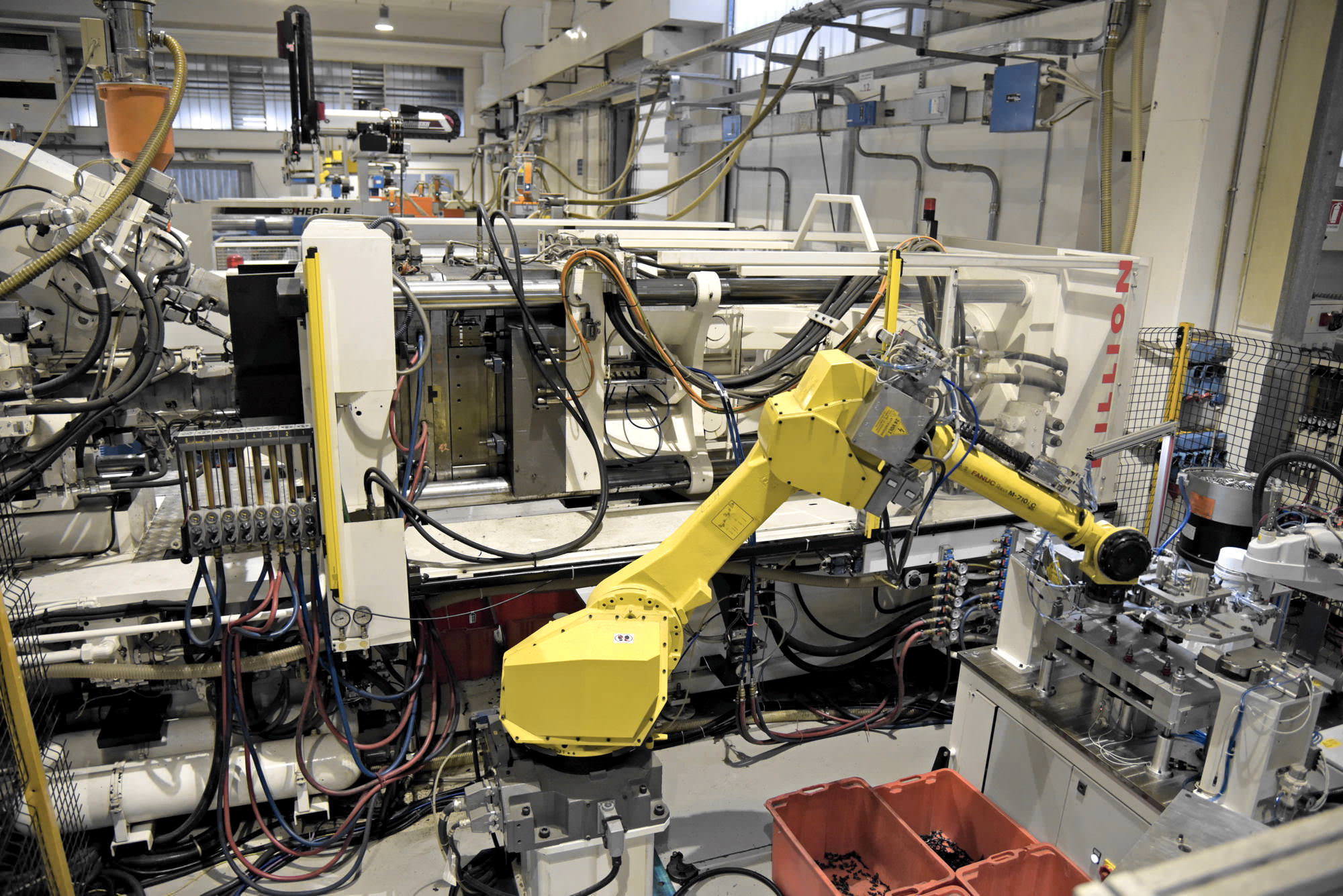

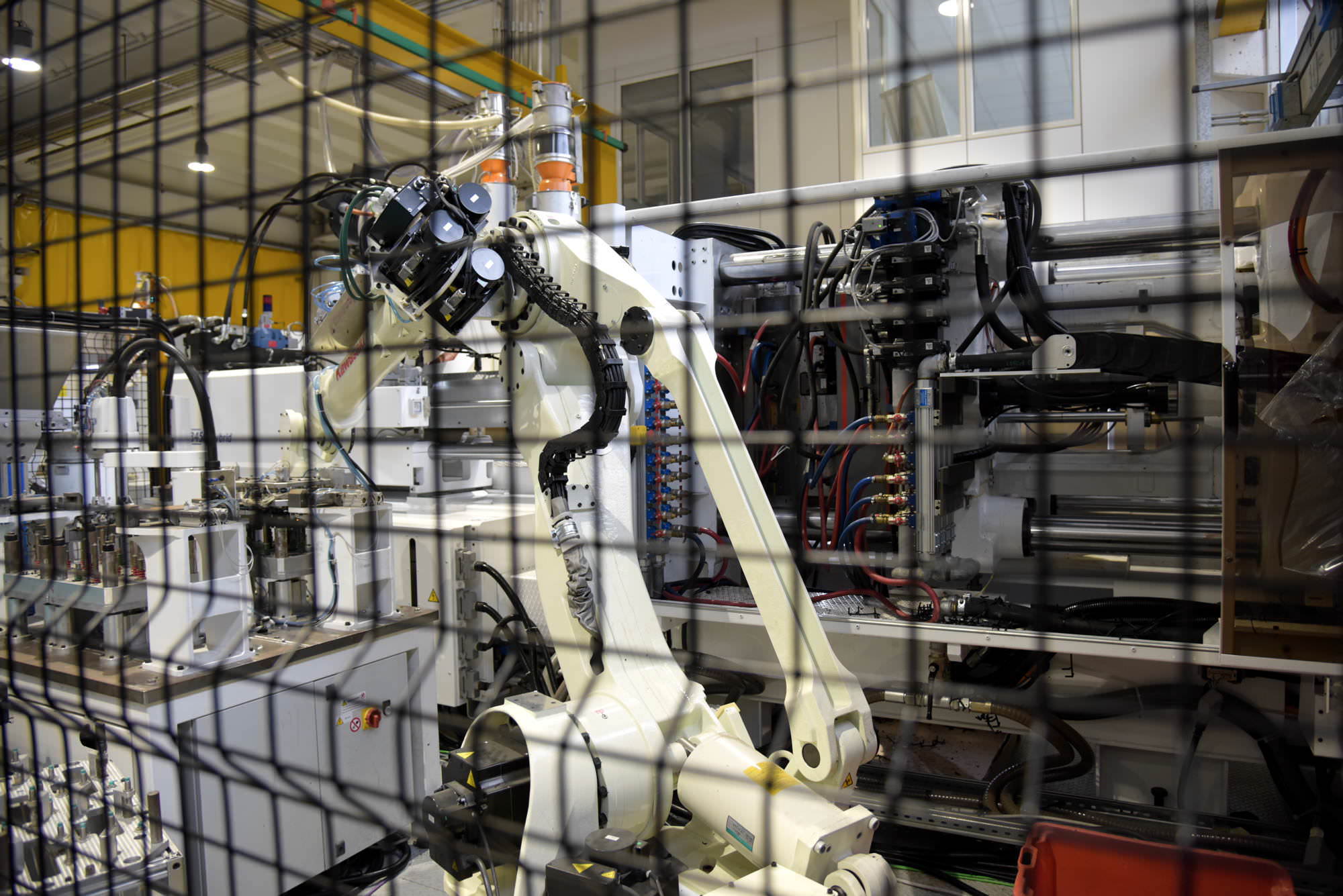

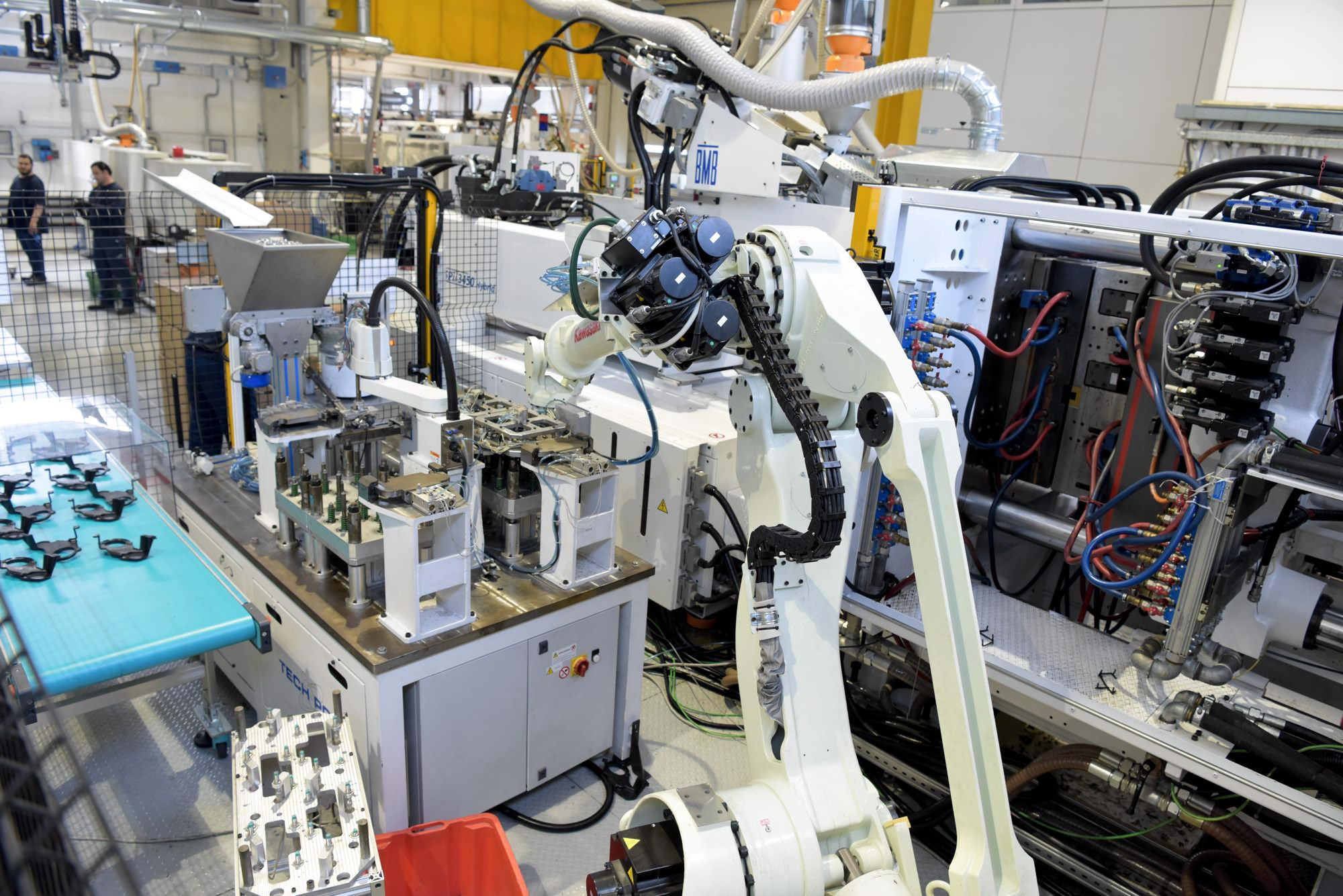

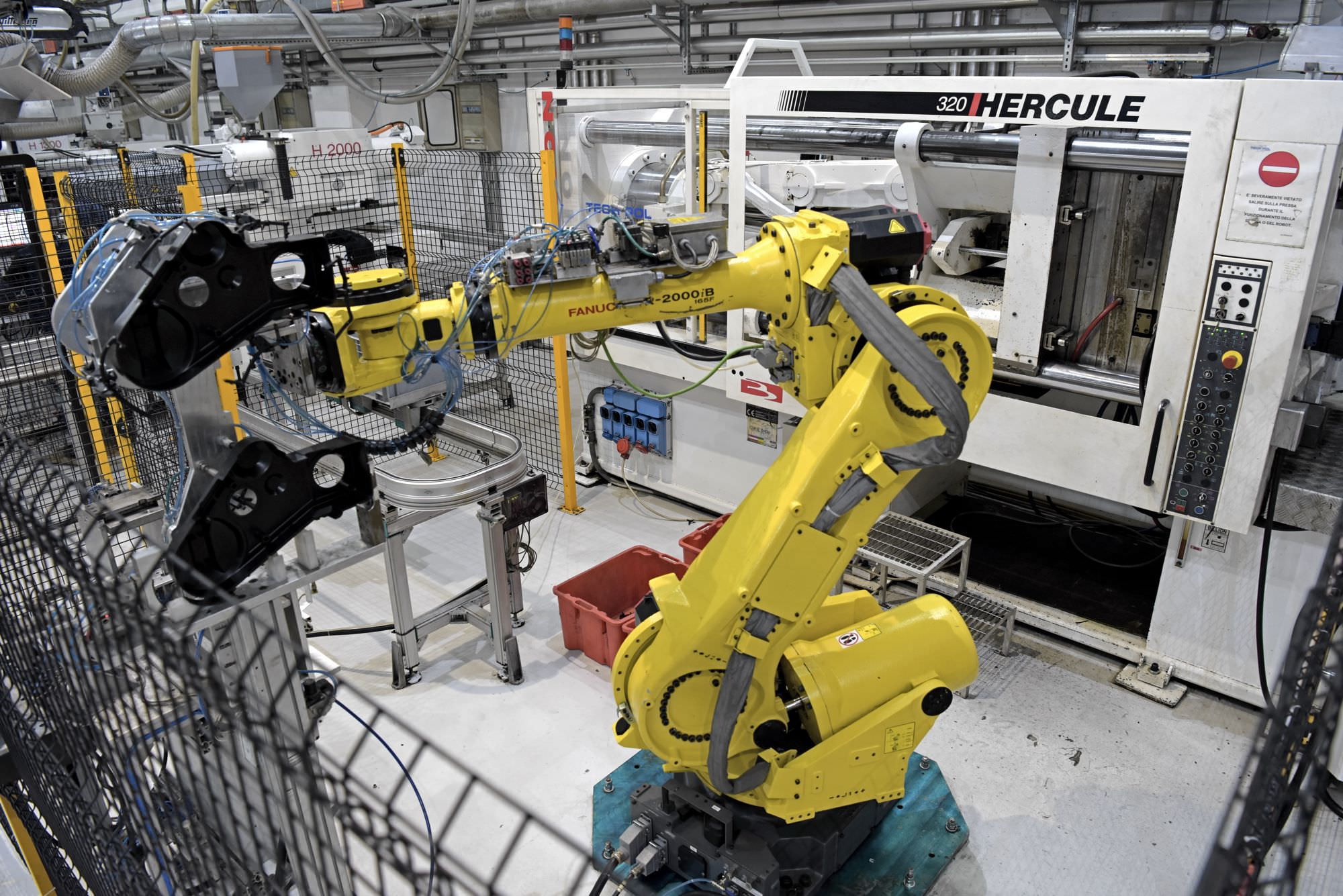

Our machine fleet consists of 51 injection moulding machines, of which 12 are Bi-Material with power ranging from 50 to 850 tons.

The whole production line is constantly being upgraded and has an average life of 5 years; this, with the wealth of experience gained in over 20 years with the automotive industry makes Techpol Srl one of the top range businesses in the world, in terms of its quality and production standards.

Our final assembly department is equipped with: