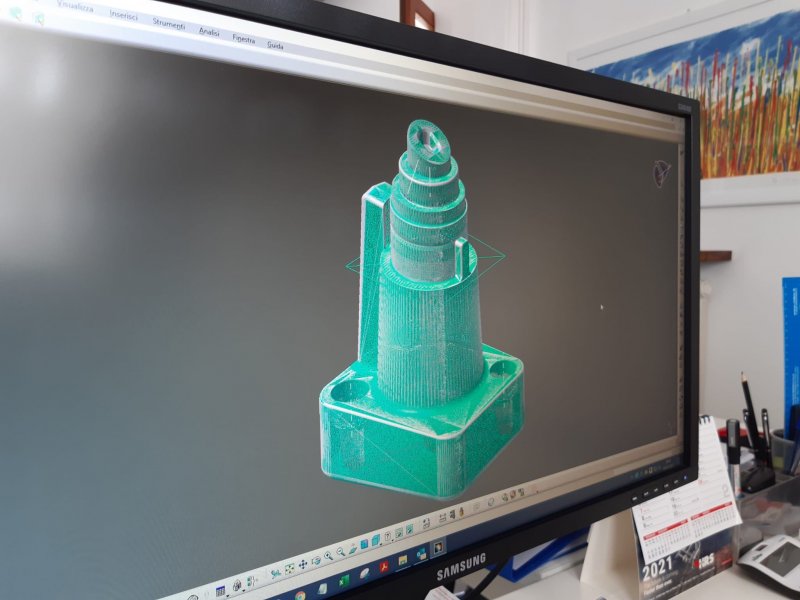

TechPol has upgraded its computer aided engineering software with two new design and finite element simulation tools:

- Solidworks flow simulation

- Solidworks simulation premium

with the aim of improving the technical support for its customers, during the design and industrialisation activities of their plastic components.

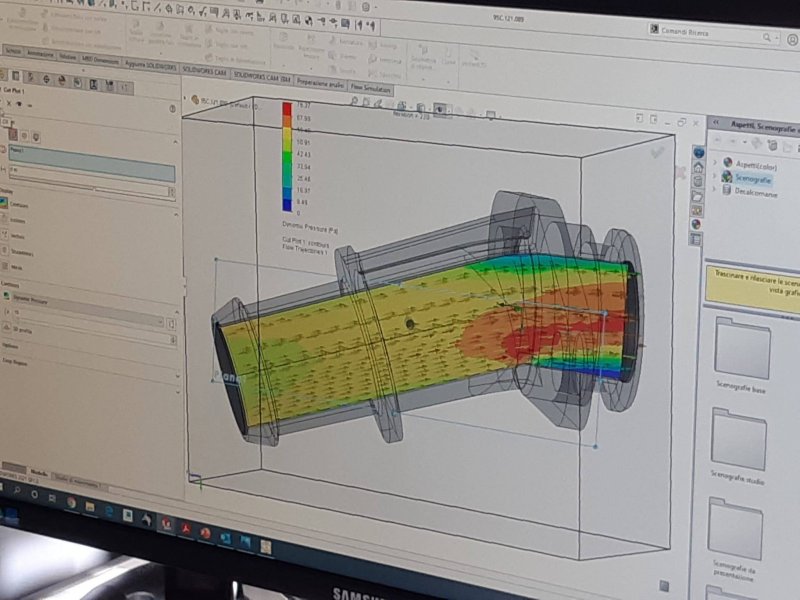

SOLIDWORKS Flow Simulation gives product engineers access to powerful CFD (computational fluid dynamics) analysis capabilities that help enable them to speed up product innovation.

Flow Simulation’s array of visual results like Flow Trajectories and Cut plots can help determine qualitatively why a design is behaving the way it is, and how it might be improved, taking into account the compromise with the injection moulding requirements with the aim of having a good and cost effective component.

If the fluid dynamic performance of a part is satisfactory, one can proceed to look at a plot of pressure on the inner walls of the pipe, and export those directly to SOLIDWORKS Simulation for stress analysis.

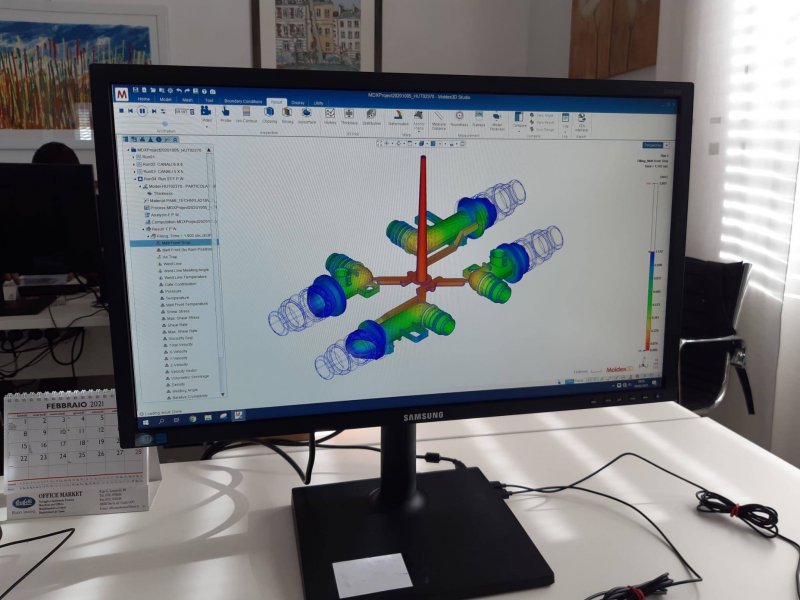

With Simulation Premium TechPol is capable of carrying out different type of simulations, such as nonlinear and dynamic response as well as composite materials:

- Simulate products made with nonlinear materials (Polymers Stress – Strain curve)

- Perform dynamic analyses of parts and assemblies

- Simulate composite materials

- Drop Test Analysis

- Frequency Analysis

- Thermal Structural Analysis - Plastic and Rubber Part Analysis

- Linear Stress Analysis

- Vibration Analysis

- Capture the effects of large displacements

These analyses will help to define which are the critical areas of a plastic part and taking them into account during the injection moulding design effort.